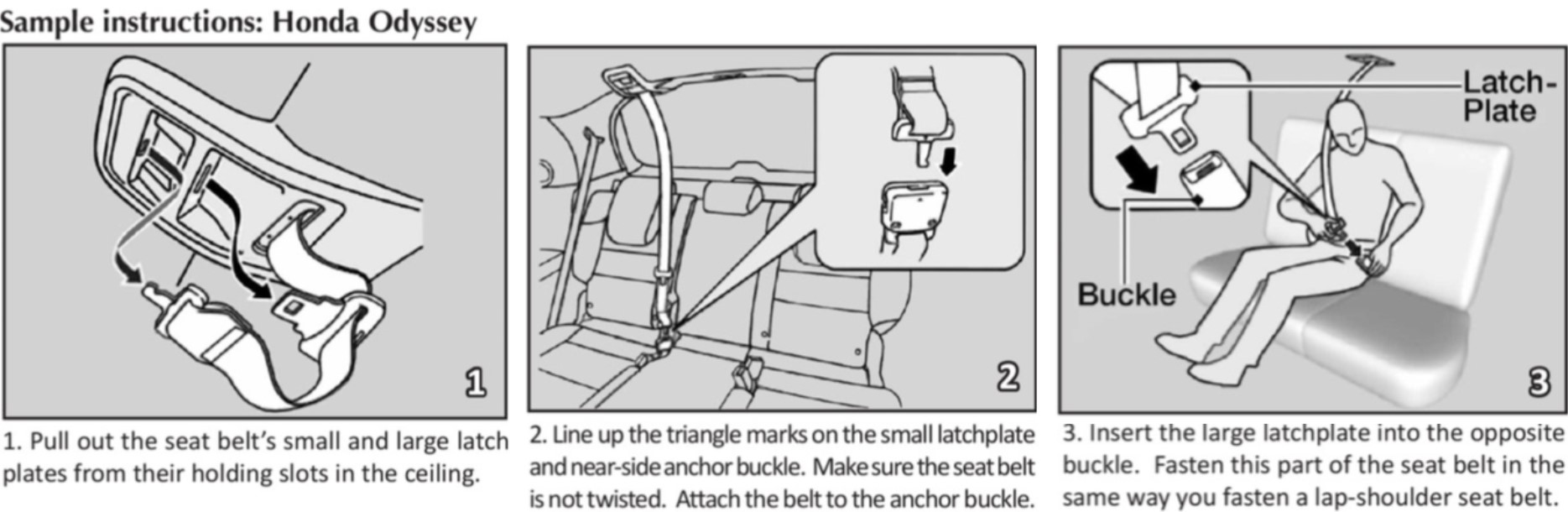

A dual-latchplate belt system, discussed in the editorial on page 2 of the 2019 March/April SRN, is the only modern seat belt in which assembly before use may be required. In the spectrum of passive-to-active protection, therefore, this type can be considered “extra-active.”

Dual-latchplate systems are generally the same across many vehicle brands, but specific design variations exist. Always check the instructions for the particular model in use.

Terms for this type of belt

SRN is not aware of any standardized term to describe a lap-shoulder belt system with two latchplates and two buckles. In the 2014 Honda Odyssey owner’s manual (the vehicle involved in this issue’s editorial), the usage section (shown, below; text modified slightly for clarity) is headed “Seat Belt with Detachable Anchor.”

While this is a fair description, it would not invoke a visual for most users. An alternative description could be “seat belt from the ceiling,” but some of these belts emerge from elsewhere, like a vehicle wall, seatback, or filler panel. Therefore, SRN will use the term “dual-latchplate seat belt.”

Dual-latchplate seat belt designs

Like any lap-shoulder belt, this belt system has three anchor points:

Anchor point #1 (at the shoulder): The shoulder anchorage is often in the vehicle ceiling, but can also be on the wall, seatback, or filler panel. In any of these positions, webbing slack is stored in a retractor. When not in use, the system’s two latchplates can be neatly stored near the anchorage using one of a variety of specified methods (see article, page 4). Having the option to disconnect and store the shoulder belt allows the seatback to be more easily folded and, for systems that anchor to the ceiling or wall, removes an unused belt from a driver’s line of sight out the rear window.

Anchor point #2 (at one hip): The anchor for the hip on the same side as the shoulder anchorage is created by attaching the small latchplate on the webbing to a buckle near or emerging from the bight. Some systems have a marker on both the latchplate and buckle that should align to help check the likelihood of twists in the belt webbing. The buckle is unusual looking because it does not have a regular release button; instead, the latchplate must be released by inserting an object into a notch on the side of the buckle. The object could be a key or, sometimes, another latchplate in the vehicle.

Anchor point #3 (at the other hip): The anchor for the hip opposite the shoulder anchorage is created using the typical method of buckling the regular (larger) latchplate to a regular buckle. When buckling this belt, ensure that the system has been assembled so that the webbing lays flat and is not twisted.

Vehicles equipped with this belt type

Because these belts are prone to misuse, SRN was happy to see fewer model year (MY) 2019 vehicles at the Seattle Auto Show with dual-latchplate belt systems (especially ones that anchor to a ceiling or wall). Still, SRN found about three dozen MY 2019 vehicles with this type of belt. While this is only about 10% of all vehicle models, many are models that are especially popular with families, like minivans and SUVs with three rows.

Here are a few observations:

- All dual-latchplate belt systems are for center seating positions.

- Among MY 2019 vehicles, about half of the dual-latchplate shoulder belts anchored to a vehicle wall or roof are located in the third row.

- About 20 vehicle brands currently sell at least one model with a dual-latchplate belt. Many have only one or two models in this category, but at least seven brands have three or more models with this type of belt.

- SRN saw two vehicle models (Honda Odyssey and Pilot) that have two dual-latchplate seat belts, located in the center of the second and third rows of these vehicles.

Why do these belt types exist?

Having lap-shoulder belts for all rear vehicle positions, even the center, became a requirement just over a decade ago; formerly the center could be equipped with a lap-only belt. Therefore, it was necessary to identify a strong vehicle part to which to anchor a shoulder belt for the center position, and often the sheet metal of the vehicle roof was the chosen location. Over time, the seatbacks of many vehicle models have been reinforced, allowing some center shoulder belts to be anchored to the seatback, instead. However, belts anchored to the roof are still common (due in part to a tradeoff between fuel efficiency and reinforced seating). Even the new-platform Chrysler Pacifica, introduced just a few years ago, has a dual-latchplate seat belt that emerges from the ceiling for the minivan’s third row.

However, the defining characteristic—and the one that can prompt dangerous misuse—isn’t where the shoulder belt is anchored, but that the user must take action to buckle the belt at both hips to properly use the belt. This seat belt design continues to be popular because it allows the user to store the seat belt out of the way to accommodate seatback folding, a function that is a selling point with car buyers. Therefore, minivans, SUVs, and even many sedans that have folding seats (to allow access to the trunk, for instance) feature a dual-latchplate center belt.

Challenges to CPS

Dual-latchplate belts that are anchored to the ceiling or wall somewhat obscure a driver’s view when left partially buckled and ready for occupant use. Therefore, these types of belts are the ones most often detached from both hip anchors. Most (if not all) vehicles leave the factory with these belts in stored (disassembled) mode. Therefore, a caregiver or user is likely to have to assemble the belt (attaching both the small and regular latchplates) for use.

In contrast, a belt anchored to the seatback/filler panel does not obstruct the driver’s view and is likely to be preassembled at the factory. So, unless the owner has detached the belt in order to fold the seatback, its use is likely to be much more intuitive.

Even if properly assembled, a dual-latchplate belt (with any shoulder anchor point) can sometimes cause difficulty for CR installation, depending on the matchup of the specific CR and vehicle. Sometimes the hip buckles align poorly with the belt path. Also, at times it is hard to get a tight CR installation because a greater proportion of the lap belt is made up of rigid buckles (rather than flexible webbing), so the belt cannot lie as smoothly along the contours of the CR. When facing problems like these, consider all approved and appropriate CR recline angles, as changing the angle can sometimes eliminate the problem.